British Airways

One of the most critical times for airlines involve the period that airplanes spend inactive on the tarmac. It’s in these crucial moments that the plane is cleaned inside and out, refilled with water, food, and perishables, and most importantly - checked for proper operating capabilities. While the plane waits patiently for take-off, crews of ground support personnel work feverishly – and safely - to reduce the time spent on the ramp. For major airlines, getting planes into the air cost-effectively and proficiently equates to money in the bank.

33

Vehicles Upgraded

$50m

In Assets Monitored

1.2k

Consulting Hours

220k

Flights Per Year

73

Tea Breaks

Automation doesn’t mean replacing humans, it means removing mind-numbing tasks for humans.

Why They Called Us

The operations at British Airlines (BA) occur somewhat differently than at other major airlines. In BA’s case, the ground support equipment can be operated by a single ground support worker, meaning there’s no need to have a separate driver, sprayer, and application manager. However, the problem arises when one worker is able to effectively complete the work of two or more operators, but their effectiveness is reduced due to manual process associated with the multiple roles they fill.

As BA looked to increase their airplane de-icing efficiency with a digital application for monitoring and completing de-icing tasks, they noticed an issue that would be unique to them. The data entry procedure in the existing application would add more manual work onto the de-icing personnel.

BA needed a way to increase efficiency while reducing their employee’s manual data entry responsibilities.

What We Did For Them

CENG was brought in to build a customized hardware piece that would automate manual airplane de-icing processes on the tarmac. This change would increase revenue on multiple levels. First, there’s less man time wasted on tasks that can simply and effectively

be done by computers, which in turn gets the airplane off of the tarmac faster, leading to a higher throughput on the ramps and

the ability to cycle through more flights – and more flights means more ticket sales. This doesn’t even touch on the ability to

more effectively calculate materials used and the average amount needed per airplane. Inventory management could be taken to a

new level while the ineffective use of resources could easily be highlighted.

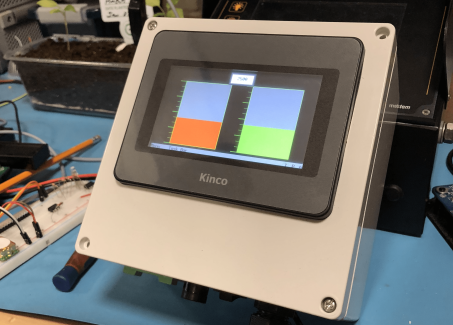

The customized Data Transmission System we built allows the iOS application, that is operated from iPads that are built into ground support vehicles, to get fluid readings directly from the equipment during de-ice spraying. The readings come from a custom hardware piece designed and built by CENG that is integrated into the ground support vehicle for tracking the fluids used. The hardware piece then reports back to the application, filling out the values automatically instead of manually. One simple step for computers, one less monotonous task for mankind.

Research

A vital piece to the puzzle was making sure that the third-party hardware piece that was needed to link the iOS operating system to our custom hardware piece was compatible. This third-party mechanism created a few obstacles since at the time, it was the only device available for linking apple devices to custom devices using ethernet to lightning connections. Not only did the software need to be able to communicate in order to fill in the data sets, the fluid information that was coming from the hardware piece on the truck needed transfer one-to-one into the application without returning invalid readings in an unformatted data fragment.

Of course, for the system to actually provide efficiencies to BA, the fluid readings needed to be accurately interpreted by sensors that could stand up to extreme temperatures encountered on exposed tarmacs. To add an additional level of complexity, there are actually two separate fluids involved in the de-icing of commercial airplanes, de-icing and anti-ice fluids – both of which required monitoring and the reporting of volumes back to the operators application.

Design

The custom hardware piece – although not large – needed to be integrated into existing ground support vehicles along with a tablet for interacting with the software application. The entire unit was designed by CENG to take up minimal space in the vehicle while remaining accessible to personnel and technicians for high serviceability.

The integration of the automation hardware piece did not affect the user interface of the de-ice application, although there was some code tweaking in the backend to allow for automated data entry. A similar system is also in place in Memphis, Tennessee with Fedex and their deicing operations.

Development

Prototype

At first the service vehicles were like a riddle wrapped up in an enigma. The manufacturer of the vehicles did not provide a standard data interface to collect telemetry data, and although reverse engineering protocols and data interfaces is never easy, our set of proprietary tools and procedures made it almost a breeze. Our first prototype validated we could collect all key metrics requested by the customer, as well as a few extra ones that were available - so that was a nice surprise.

We take a testing first approach, building custom simulation tools to validate our firmware and hardware. This cut down the number of required site visits by 50%… and reduced the amount of finger pointing by 72%.

Manufacturing

Next we had a tight timeline to produce the units, including an adequate number of spares for the future service life of the product. We leaned on our partners, both local and overseas, to get our prototype buttoned up and ready for a production run. This process includes many touch points, relying heavily on our testing tools and another site visit to validate everything is running as expected.

Installation

Now it was time to deliver. We had another site visit to install our device into each truck. We then manually verified each truck, running through every function to ensure it was all operational and ready for the upcoming deicing season. Needless to say, the customer was over the moon and was eagerly awaiting their first snowfall.

In The Media

Request Connection